-

-

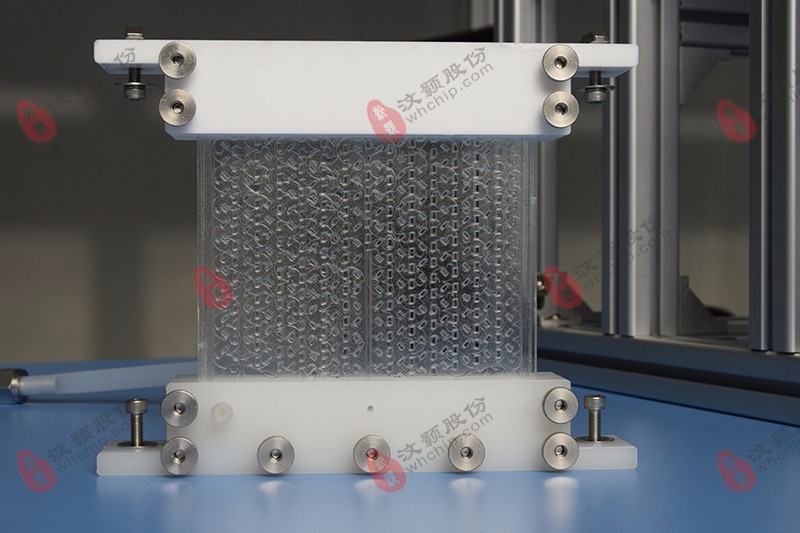

WH-IND 152 Continuous Flow Glass Microreactor

WH-IND 152 glass microreactor is a microchannel reactor researched and developed independently by Wenhao Co.,LTD. It has the independent intellectual property rights. The microreactor has the advantag

WH-IND 152 glass microreactor is a microchannel reactor researched and developed independently by Wenhao Co.,LTD. It has the independent intellectual property rights. The microreactor has the advantages of large specific surface area, high mass and heat transfer efficiency, high safety and small amplification effect. WH-IND 152 glass microreactor takes into account both mass transfer and pressure drop, enabling ultra-high-efficiency mass transfer and heat transfer, safely and stably producing pilot and pilot production processes for APIs and related synthetic processes.

Glass microchannel reactor Applications:

Pharmaceutical Intermediates, Pharmaceutical Synthesis (Including Outsourcing), Fine Chemicals, Pesticide Chemistry, Specialty Chemicals, Commodity Industry, Nanomaterials, Polymer Modification, etc.

Glass microchannel reactor technology can be realized Case:

1, Michael addition reaction

2, pay - grams of alkylation reaction

3, aldol reaction (sodium ethoxide)

4, sulfonation, nitration

5, diazotization reaction, azidation reaction

6, solvent-free reaction, 30% liquid-liquid phase reaction (high probability)

Glass microchannel reactor Features:

1, flux: 50-150 tons / year

2, excellent corrosion resistance (process side): Compatible with all reagents except 30% KOH, molten alkali metal, HF, strong corrosion reagent can be long-term stable operation

3, Free combination configuration: highly flexible modular design to ensure that all kinds of process requirements can be adapted

4, heat exchanger side and the process side of integrated processing, each module contains a technology board and two heat exchange board

5, excellent mass transfer and heat transfer performance

6, temperature range: -25-195 ℃

7, the pressure range: 0-20bar